Leave Your Message

When it comes to operating a successful restaurant, a reliable and efficient Restaurant Ice Machine is an essential asset. According to a recent industry report by IBISWorld, the restaurant equipment manufacturing sector is projected to reach $16 billion by 2026, highlighting the growing demand for efficient appliances that cater to the specific needs of foodservice establishments. Ice machines, in particular, play a critical role in maintaining customer satisfaction and enhancing the overall dining experience, whether it's providing chilled beverages or preserving food freshness.

Expert John Smith, a leading consultant in the commercial kitchen equipment industry, emphasizes the importance of selecting the right ice machine. He states, “Investing in the right Restaurant Ice Machine not only improves operational efficiency but also ensures that your establishment can handle peak service times without compromising on quality.” With various types and sizes of ice machines available, understanding how to choose one that aligns with your restaurant's specific requirements can significantly impact your operational efficiency and customer service.

In this ultimate guide, we will explore the key factors to consider when selecting a Restaurant Ice Machine, ensuring that restaurant owners can make informed decisions that will enhance their service quality and operational productivity.

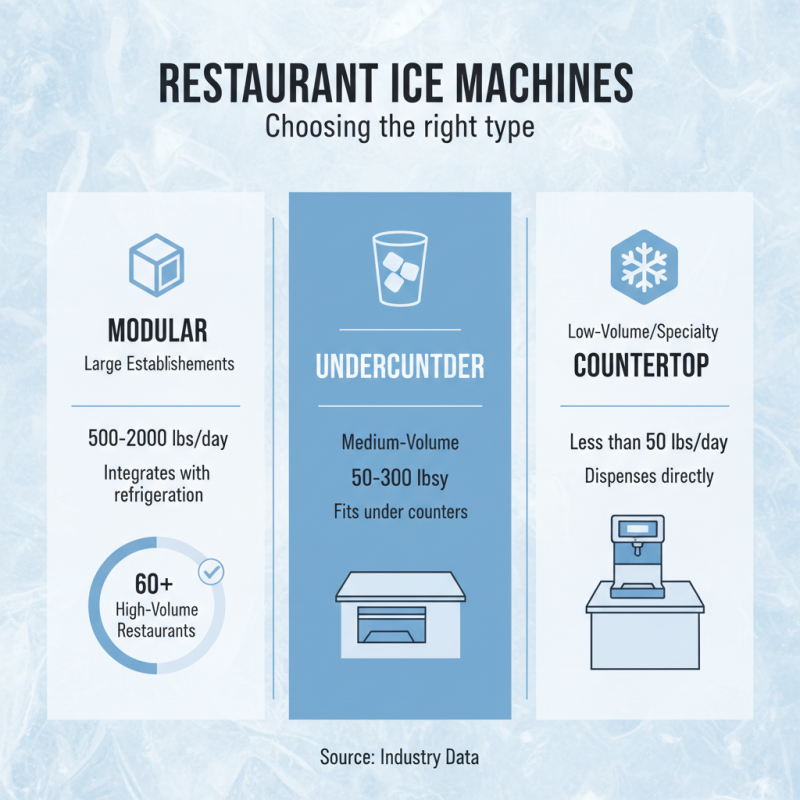

When selecting an ice machine for a restaurant, understanding the various types available is crucial for meeting specific operational needs. Commercial ice machines predominantly fall into three categories: modular, undercounter, and countertop units. Modular machines are designed for larger establishments, capable of producing significant quantities of ice daily—ranging from 500 to 2,000 pounds. According to industry data, over 60% of high-volume restaurants prefer modular machines due to their efficiency and adaptability, allowing for easy integration with existing refrigeration systems.

Undercounter ice machines, on the other hand, are ideal for smaller restaurants or bar areas where space is limited. These compact units typically produce between 300 and 600 pounds of ice per day, making them suitable for businesses that require moderate ice production without sacrificing valuable floor space. The National Restaurant Association reports that as dining trends shift toward more intimate venues, the demand for undercounter options has increased by nearly 25% in just the past two years.

Lastly, countertop ice makers offer a unique solution for establishments needing immediate access to ice in smaller quantities. With production capabilities of 100 to 300 pounds per day, these units are perfect for cafe settings or mobile food trucks. Recent surveys indicate that 35% of food service operators are now exploring countertop models to enhance service flexibility while reducing upfront costs. Understanding these types of ice machines will not only streamline operations but can also significantly impact overall customer satisfaction.

When selecting the best restaurant ice machine for your needs, there are several key factors to consider. First and foremost, the production capacity of the machine is critical. Assess your restaurant's daily ice requirements based on the type of service you provide. For instance, a busy establishment that serves numerous customers throughout the day will need a machine that can produce large quantities of ice quickly. On the other hand, a smaller venue may suffice with a compact model that handles lower volumes.

Another important factor is the type of ice produced by the machine. Different types of ice serve various purposes in food and beverage service. For example, clear, hard cubes might be ideal for cocktails, while flaked ice may be better suited for serving seafood. Consider how the ice type impacts your specific offerings and customer experience. Additionally, think about the machine's maintenance requirements and energy efficiency. Machines that are easier to clean and maintain can save time and reduce operational costs in the long run, making them an important aspect to evaluate in your decision-making process.

When selecting a restaurant ice machine, understanding ice production capacity and size requirements is crucial. According to the Food Service Equipment Reports, varying restaurant types demand different ice volumes; for instance, a fine dining establishment may require approximately 3,000 pounds of ice per day, while a fast-food operation might need around 1,500 pounds. The production capacity of ice machines typically ranges from 250 to 1,500 pounds of ice in 24 hours, which is an essential metric to consider based on your establishment's projected customer traffic and seasonal variations.

Additionally, physical size is also a key consideration. The footprint of the ice machine must fit seamlessly within your kitchen layout without disrupting workflow or efficiency. Standard ice machines can range from compact models that occupy a mere 20 square inches to larger units needing over 40 square inches. The National Restaurant Association notes that space constraints often influence machinery choices, particularly in urban settings. Therefore, accurately assessing both your ice production needs and physical space can lead to a more informed decision, ultimately ensuring that your restaurant maintains excellent service standards while managing operational costs efficiently.

When selecting the best restaurant ice machine, one of the crucial factors to consider is the energy efficiency ratings. These ratings indicate how much energy the machine consumes in relation to its ice production capacity. Higher energy efficiency translates to lower operating costs, which is essential for maintaining a profitable restaurant. Investing in an energy-efficient ice machine can significantly reduce electricity bills, thereby improving the overall financial performance of your establishment. Additionally, many energy-efficient models utilize advanced technologies that not only decrease energy consumption but also enhance ice production quality and speed.

In addition to energy efficiency, understanding the operating costs associated with different ice machines is vital. These costs encompass not only electricity but also water usage and maintenance expenses. Restaurants should evaluate the total cost of ownership over the machine's lifecycle rather than just upfront pricing. Machines that may seem cheaper initially might lead to higher costs over time due to lower efficiency or frequent breakdowns. Conducting a thorough analysis of both energy usage and maintenance requirements can aid in selecting a model that balances initial investment with long-term savings, ensuring you make a well-informed decision that fits your restaurant's operational needs.

This chart illustrates the energy efficiency ratings and average operating costs of various types of restaurant ice machines. Energy efficiency is measured in kilowatt hours (kWh) per 100 lbs of ice produced, while operating costs are reflective of electricity expenses incurred monthly based on average usage.

Maintaining your restaurant's ice machine is crucial for ensuring consistent ice production and extending the lifespan of the equipment. According to a report by the Food and Beverage Equipment Report, poorly maintained ice machines can lead to a 30% decrease in output efficiency. Regular cleaning and sanitization are vital in preventing the buildup of bacteria and mineral scale, which can reduce the quality of ice and ultimately affect the health of customers. Industry experts recommend a thorough cleaning at least once every six months, with weekly inspections to identify any early signs of wear or contamination.

In addition to regular cleaning, it's essential to monitor and maintain the water quality supplied to your ice machine. High mineral content in water can lead to scaling, which not only impairs functionality but can also shorten the life of the machine. The Water Quality Association suggests that restaurants use filtered water to improve the efficiency of their ice machines. Furthermore, maintaining the right ambient temperature around the machine can significantly impact its performance. Keeping the surrounding area well-ventilated helps to prevent overheating, which can disrupt production and lead to costly repairs. Investing time and resources into diligent maintenance practices can pay dividends in the long run, ensuring your ice machine remains a reliable asset in your establishment.

| Type of Ice Machine | Production Capacity (lbs/day) | Energy Efficiency Rating | Maintenance Frequency (Months) | Typical Lifespan (Years) |

|---|---|---|---|---|

| Modular Ice Machine | 800 | A+ | 6 | 10 |

| Under-Counter Ice Machine | 300 | B | 4 | 7 |

| Batch Ice Machine | 500 | A | 5 | 8 |

| Portable Ice Machine | 150 | C | 3 | 5 |

| Nugget Ice Machine | 400 | B+ | 4 | 6 |