Leave Your Message

When it comes to running a business that relies on a steady supply of ice, choosing the right equipment is paramount. An Industrial Ice Maker plays a crucial role in various industries, from food and beverage to healthcare and hospitality. Selecting the best ice maker for your specific business needs can significantly impact your operational efficiency, customer satisfaction, and overall profitability. With numerous models available on the market, understanding your requirements and the features of different machines becomes essential.

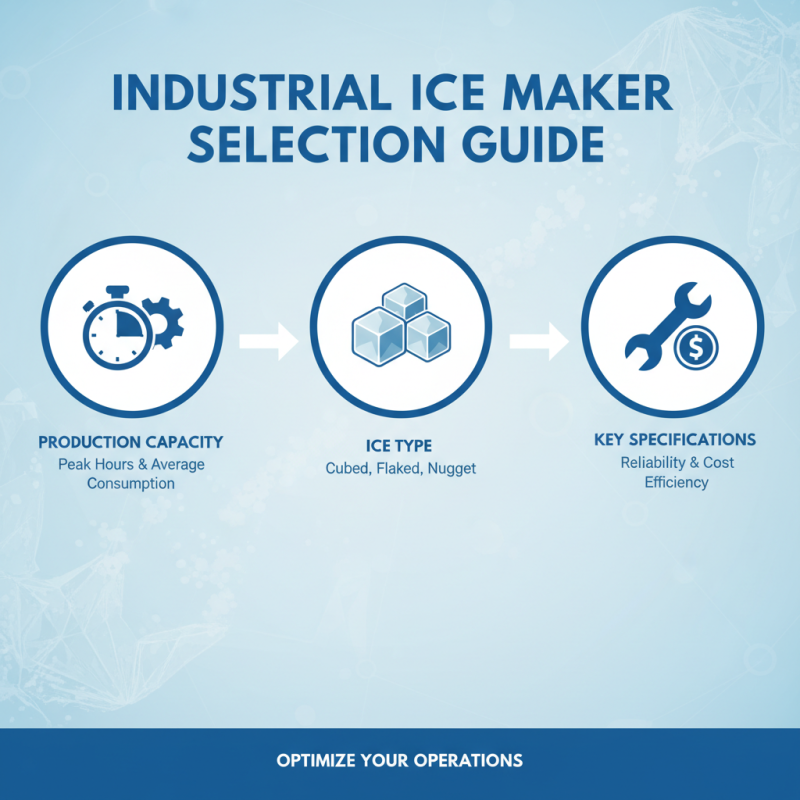

In this article, we will explore the key factors to consider when choosing an Industrial Ice Maker, including production capacity, ice type, energy efficiency, and maintenance requirements. By evaluating these aspects, you can make an informed decision that aligns with your business operations. Whether you need large volumes of clear ice for a bustling restaurant or specialized ice for a medical facility, the right industrial ice maker can enhance your service quality and ensure that you never run out of this critical resource.

Industrial ice makers play a crucial role across various sectors, including food and beverage, healthcare, and hospitality. Understanding the different types and applications can help businesses select equipment that meets their specific needs. The most common types of industrial ice makers are flake ice, nugget ice, and block ice machines. Each type serves distinct functions; for instance, flake ice is popular in seafood markets and restaurants due to its ability to mold easily around products, maximizing cooling efficiency. A report from the IHS Markit indicates that the demand for flake ice machines has increased by 15% over the past five years, driven by the rising emphasis on food safety and presentation.

Moreover, the applications of industrial ice makers extend beyond food preservation. In the healthcare sector, ice is often used for therapeutic purposes and to maintain the integrity of certain medicines and biological samples. Nugget ice, known for its chewable texture, is increasingly favored in hospitals and clinics for patient hydration as it enhances the drinking experience. According to research by the Association of Ice Makers, the growth in healthcare applications alone has contributed to a 10% increase in overall ice maker sales in the last year. The versatility and efficiency of industrial ice makers make them indispensable tools in several industries, underscoring the importance of thorough understanding when selecting the right model for a business’s operational requirements.

This bar chart compares the production capacities of various types of industrial ice makers. Each type serves different business needs and industries, showcasing their performance in kg of ice produced per day.

When selecting an industrial ice maker for your business, several key specifications should be at the forefront of your decision-making process. The production capacity of the ice maker is crucial; it determines how much ice is generated within a specific time. Consider your business's peak hours and average ice consumption to select a model that meets your demands without overwhelming your operations. Additionally, understand the ice type produced—whether you need cubed, flaked, or nugget ice—as different types serve distinct purposes in various industries.

Another vital specification to evaluate is energy efficiency. Industrial ice makers can consume significant amounts of energy, affecting your operating costs. Look for models with high energy efficiency ratings and features that minimize waste. Further, ease of maintenance plays a critical role in the longevity and effectiveness of an ice maker. Models that allow easy access to components for cleaning and repairs can save both time and money in the long run.

**Tips:** Always check customer reviews and seek recommendations before purchasing. This can shed light on the reliability and performance of different models. Additionally, consider the space where you will install the ice maker; ensure it has adequate ventilation and meets size requirements to avoid complications during operation.

When considering industrial ice makers, a comparative analysis of leading brands reveals distinct advantages and features tailored to diverse business needs. The key factors to evaluate include production capacity, energy efficiency, and ease of maintenance. Brands often differ significantly in their output capabilities, with some models capable of producing thousands of pounds of ice per day, making them ideal for high-demand environments such as restaurants, hospitals, and large-scale events. Companies should assess their specific volume needs to choose an appropriate model that can sustain their operational requirements without overextending their budget.

Energy consumption is another critical consideration, as industrial ice makers can contribute significantly to a business's overall utility costs. Some brands prioritize energy-efficient designs, incorporating advanced technology that not only reduces electricity usage but also minimizes water waste. Additionally, ease of maintenance varies among models; manufacturers that offer accessible service points and streamlined replacement parts can save businesses time and money in the long run.

Ultimately, a thorough comparative analysis will help decision-makers align their choice with operational priorities while optimizing overall performance, cost-efficiency, and sustainability in the workplace.

When selecting an industrial ice maker, energy efficiency is a crucial factor that can significantly impact your operational costs. An energy-efficient ice maker uses less electricity while still providing the necessary output of ice, which translates to lower monthly utility bills. Additionally, more efficient machines tend to have a longer lifespan, resulting in fewer replacements and reduced maintenance costs over time. Understanding the energy ratings of different models can help you make an informed decision that aligns with your business needs.

Tips for maximizing energy efficiency in your ice-making operation include regular maintenance checks to ensure that your machine is running optimally. Cleaning the condenser coils and ensuring proper airflow can prevent overheating and enhance performance. Also, consider installing the unit in a well-ventilated area to further improve energy efficiency. Monitoring your ice production against demand is vital; producing too much ice can lead to unnecessary energy waste, so adjust settings as needed to match usage.

Furthermore, investing in technology that allows for better monitoring of energy consumption can provide valuable insights. Using smart meters or energy management systems can help you analyze usage patterns, identify inefficiencies, and make strategic adjustments to reduce costs. By prioritizing energy efficiency, your business can not only lower operational expenses but also contribute to more sustainable practices within the industry.

Maintaining an industrial ice maker is crucial for ensuring its longevity and optimal performance. Regular cleaning is one of the most important aspects of maintenance. This includes descaling the unit to remove mineral buildup and cleaning the bin and evaporator to prevent contamination. It is recommended to establish a cleaning schedule based on the frequency of use and the quality of the water being used. A systematic approach to cleaning not only maximizes efficiency but also enhances the quality of the ice produced.

In addition to routine cleaning, checking and replacing filters is vital for the operational efficiency of the ice maker. Clogged filters can restrict airflow and diminish cooling efficiency, leading to higher energy consumption and potential breakdowns. Inspecting components such as hoses, valves, and electrical connections regularly can help identify issues before they escalate. Keeping an eye on these elements ensures that the ice maker runs smoothly, extending its lifespan and reducing the need for costly repairs. Integrating these maintenance practices into your operational routine can significantly enhance the reliability and durability of your ice-making equipment.