Leave Your Message

Choosing the right Commercial Ice Maker Machine is vital for any business that prioritizes customer satisfaction and efficiency. A recent industry report highlighted that 66% of restaurants and bars consider ice quality crucial to their service. The right ice maker not only impacts drink presentation but also affects operational workflow. Many businesses overlook the significance of selecting the appropriate machine for their specific needs.

High demand during peak hours can put pressure on an inadequate ice maker, leading to service delays. It is not uncommon for a machine that seemed sufficient to fall short. For instance, restaurants might face complaints due to inconsistent ice availability. Additionally, research indicates that improper ice production can lead to increased costs and wasted resources.

Inadequate planning can result in costly errors. Choosing a Commercial Ice Maker Machine requires assessing production capacity, ice type, and space considerations. It's essential to understand these factors and reflect on past experiences. Investing in a quality machine can significantly influence operational success.

Understanding your business needs for ice production is essential. Different industries have distinct requirements. For example, a restaurant may require a small ice maker, while a hotel needs a larger machine to cater to multiple guests. According to industry reports, restaurants typically use between 500 to 1,500 pounds of ice daily. This information helps in assessing potential ice maker capacities.

The type of ice also matters. Some businesses prefer cubed or flaked ice for cocktails, while others need nugget ice for soft drinks. A report from the International Ice Association shows that 70% of customers prefer nugget ice due to its chewability. Therefore, understanding your target customers can influence your choice.

Consider peak business hours too. If your establishment is busy during lunch, an appropriate machine should keep up with demand. It’s frustrating to run out of ice during service. Some establishments reported having to close early due to inadequate ice supply. Such issues can impact customer satisfaction and revenue. Assessing both daily needs and peak demands will help in making a smarter choice.

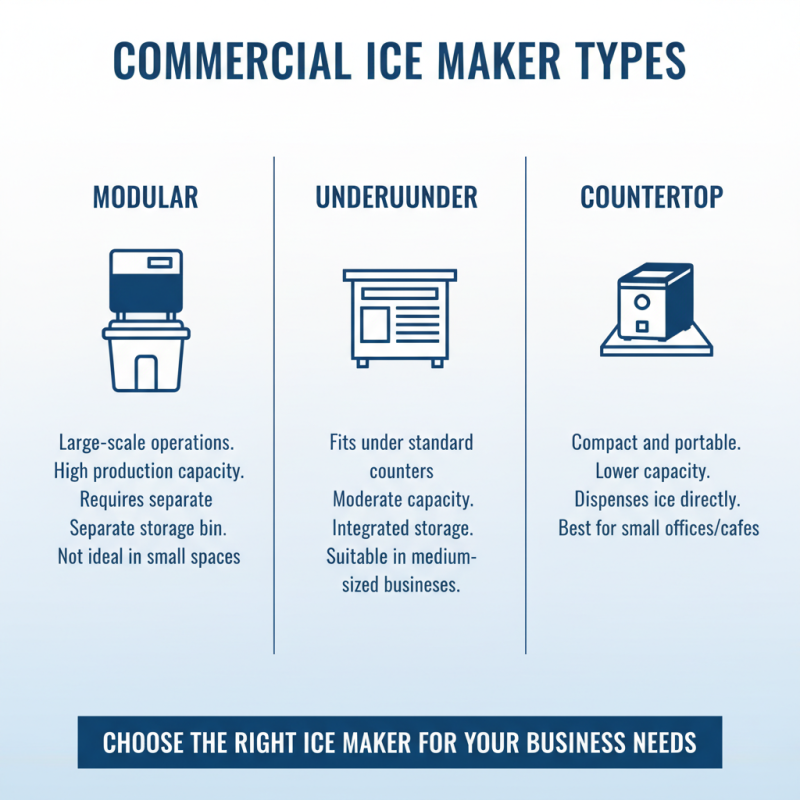

When selecting a commercial ice maker machine, understanding the types available is essential. There are three primary categories: modular, undercounter, and countertop models. Modular machines are often the best choice for large-scale operations. They produce a significant amount of ice and can be paired with bins for storage. Their size can be challenging in smaller locations, causing some businesses to reconsider.

Undercounter ice makers are compact, fitting neatly under countertops. They work well for bars and cafes. Their limited production might not meet the needs of high-demand events. It's important to evaluate your ice needs to avoid shortages during peak periods. Countertop models offer convenience for small setups. They provide low volumes, ideal for quick service. However, their smaller capacity can be a drawback for bigger businesses.

Each type of ice maker has distinct features, impacting your choice. For instance, some machines offer different ice shapes, like cubes or nuggets. The ability to customize ice shape is crucial for certain beverages. Energy efficiency is another factor to consider, as machines consume varying amounts of power. A quiet model may be preferable in a quiet dining area, but might be more expensive. Balancing these features with your budget can be tricky.

Choosing the right location for an ice maker is crucial. Consider the layout of your business. The ice maker should be easily accessible for staff. Ideally, it should be close to areas where ice is frequently used. Think about the workflow in your kitchen or bar.

Evaluate the available space. Ice makers come in various sizes. Measure the area where you plan to install the machine. Make sure there’s adequate clearance for ventilation. Don't forget about the plumbing and electrical connections. These should be nearby to avoid extra work and cost.

Don’t overlook temperature and humidity levels. Hot, humid environments can impact ice production. If the area is too warm, ice may melt too quickly. Regularly assess the space. It may require adjustments as your business grows. Keeping an open mind about flexibility can lead to better efficiency.

When selecting a commercial ice maker, understanding ice production capacity and speed is crucial. Each business has unique needs. Restaurants may require fast production for busy hours. Cafes might need a steady supply for drinks. Identify your peak hours to determine the right output.

Consider how much ice you will use daily. A high turnover might demand machines capable of producing hundreds of pounds per day. For a smaller café, a lower output could suffice. Pay attention to the machine’s cycle time as well. Some machines can produce ice in just a few minutes, while others take longer.

Be aware of potential issues. A machine that seems perfect may struggle during peak times, causing delays. Is it energy-efficient? Large production may lead to a spike in your utility bills. Assess the size and weight of the machine. Ensure it fits well in your space. It's about finding a balance between capacity, efficiency, and practicality.

When budgeting for a commercial ice maker, it’s crucial to consider various factors. The average cost can range from $3,000 to over $10,000, depending on capacity and features. A report from IBISWorld highlights that a well-chosen ice maker can significantly impact operational costs. The features you select will also affect your bottom line.

Here are a few tips: Evaluate your business needs carefully. Are high ice production rates critical? Larger units often require higher upfront costs but can save money over time. Energy-efficient models can lead to savings on utility bills. Research shows that energy-efficient machines can reduce energy usage by up to 50%.

Another key consideration is maintenance. Ice makers require regular cleaning and service. This can be an ongoing cost that adds up. Aim to establish a maintenance budget of about 10% of the initial purchase price annually. Be open about potential repairs arising from wear and tear. A plan can prevent unexpected expenses.

Always factor in ice storage needs. A machine that produces too much or too little ice can lead to additional costs. Analyze your peak hours and average sales. Avoid the common mistake of underestimating your ice requirements. Each of these insights can guide you toward making a more informed decision.

This bar chart illustrates the average costs associated with different tiers of commercial ice maker machines. Choosing the right type depends heavily on your business needs and budget.