Leave Your Message

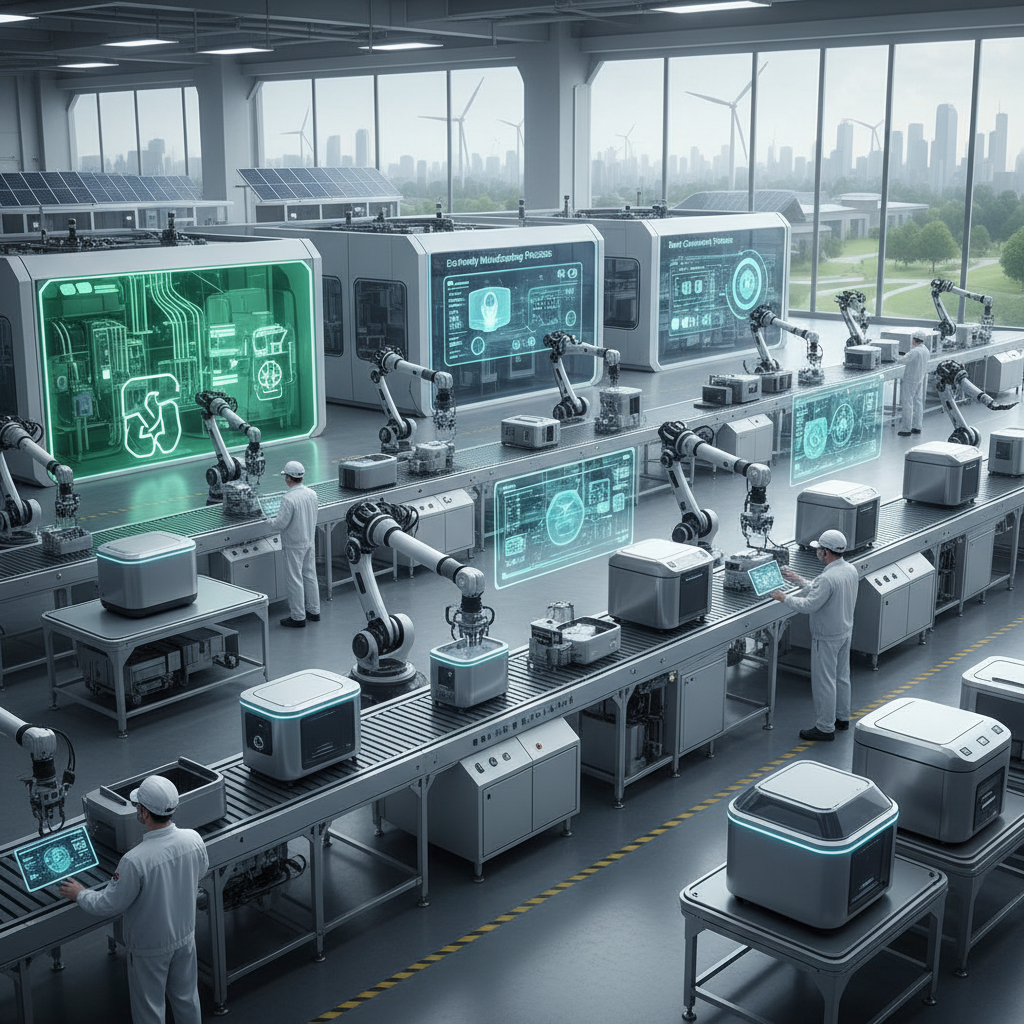

As we look toward 2025, the landscape of home and commercial refrigeration is poised for transformation, with advancements driven by cutting-edge technology and innovative design. At the forefront of this evolution is the Ice Maker Factory, where engineers and designers are reimagining how we produce and utilize ice. The demand for efficient, sustainable, and smart ice-making solutions is greater than ever, as consumers and businesses alike seek to optimize their operations while reducing their environmental footprint.

This article will delve into the top five innovations emerging from the Ice Maker Factory that promise to reshape the industry in the coming years. From eco-friendly manufacturing processes to smart connectivity features that enhance user experience, these innovations reflect a commitment to sustainability and efficiency. By exploring these advancements, we will gain insight into how the Ice Maker Factory is not only keeping pace with market demands but also setting new standards for future ice production. Join us as we uncover the groundbreaking technologies that will define the ice-making landscape in 2025.

As we look forward to 2025, the ice maker industry is poised for transformative advancements that promise to revolutionize efficiency. One of the most notable innovations is the integration of smart technology into ice makers. These devices will utilize sensors and IoT connectivity to monitor usage patterns, streamline production schedules, and minimize waste. This not only enhances operational efficiency but also significantly reduces energy consumption, aligning with global sustainability goals.

Additionally, advancements in materials and engineering designs are set to enhance ice production capabilities. New thermal insulation techniques and eco-friendly refrigerants are being developed to ensure rapid freezing processes, decreasing the time required to produce high-quality ice. Coupled with modular designs that allow for easy upgrades and serviceability, these innovations mark a significant shift towards more user-friendly and sustainable ice-making solutions. As manufacturers embrace these technologies, consumers can expect ice makers that are not only smarter but also far more efficient than their predecessors.

As the demand for ice increases globally, smart technology integration in ice production systems is set to revolutionize the industry by 2025. According to a recent report by IBISWorld, the ice manufacturing industry is projected to grow at an annual rate of 3.4% over the next five years, largely driven by innovations in energy efficiency and automation. The incorporation of IoT devices within ice makers allows for real-time monitoring and management, reducing waste and optimizing production cycles. This data-driven approach not only enhances operational efficiency but also aligns with contemporary sustainability goals, as companies seek to minimize their carbon footprints.

Tip: When exploring new ice makers, prioritize models that offer smart technology features. Look for energy efficiency ratings and programmable settings that allow you to customize ice production based on your needs.

Additionally, advancements like predictive analytics in maintenance are set to reduce downtime significantly. With AI-driven systems, manufacturers can analyze usage patterns and alert operators before equipment failures occur, streamlining operations and saving costs. This proactive maintenance strategy is invaluable, especially in commercial settings where ice supply is crucial.

Tip: Implementing a regular maintenance schedule supported by smart alerts can help extend the lifespan of your ice production equipment and ensure consistent performance.

As we look towards 2025, the ice maker manufacturing sector is seeing a remarkable shift towards eco-friendly innovations that align with global sustainability goals. Startups and established manufacturers are increasingly adopting renewable energy sources and minimizing energy consumption in their production processes, reflecting a broader industry trend towards greener practices. This transition not only addresses environmental concerns but also caters to a growing consumer demand for sustainable products. The integration of intelligent technologies further enhances efficiency, offering compelling solutions for modern refrigeration challenges.

In particular, advancements in ice storage solutions are noteworthy. Innovative cold plate technologies are being developed to enhance energy efficiency, reducing waste and lowering operational costs. Manufacturers are also exploring alternative refrigerants that have a lower global warming potential, helping to mitigate climate change impacts. As these initiatives gain traction, the ice maker industry is poised for significant transformation, making strides not just in technological capabilities but also in the environmental responsibility that defines the future of manufacturing.

As the ice maker industry evolves, advanced customization features are taking center stage to enhance consumer satisfaction. More manufacturers are integrating smart technology, allowing users to tailor their ice-making preferences according to specific needs.

For instance, some models now enable users to choose the size, shape, and density of ice cubes, catering to various beverages and occasions. This level of personalization not only improves user experience but also demonstrates a commitment to meeting the diverse demands of consumers.

Tips for enhancing your ice-making experience include considering your usual consumption patterns. If you frequently host gatherings, opt for machines that produce larger quantities of ice quickly. Additionally, look for models equipped with user-friendly apps that allow remote control adjustments and monitoring. These features offer convenience, ensuring you always have the perfect amount of ice ready when you need it.

Many forward-thinking brands are also focusing on aesthetic customization, allowing consumers to select finishes and colors that complement their kitchen décor. This trend reflects a broader movement towards personalized home appliances, transforming functional items into stylish pieces that resonate with individual tastes.

In 2025, ice maker factories are set to embrace groundbreaking innovations, particularly in predictive maintenance and smart monitoring technologies. These advancements will enhance operational efficiency, significantly reducing downtime and maintenance costs. By integrating artificial intelligence and machine learning, manufacturers will be able to anticipate potential issues before they become critical, ensuring that ice production remains uninterrupted.

Moreover, smart monitoring systems will allow manufacturers to collect and analyze real-time data, providing insights into machine performance and energy consumption. This data-driven approach not only improves the reliability of ice makers but also promotes sustainability by optimizing resource usage. As factories implement these technologies, they will be better equipped to respond to market demands swiftly and efficiently.

**Tips for Implementing Smart Monitoring:**

1. Invest in IoT-enabled sensors that track machine performance and environmental conditions.

2. Regularly train maintenance staff on new technologies to ensure they can effectively troubleshoot issues.

3. Establish a routine review process for the data collected, allowing for timely adjustments to production strategies.