Leave Your Message

Choosing the right Ice Machine Factory is crucial for your business success. An efficient ice machine enhances service quality, especially in the food and beverage sector. However, not all factories provide the same level of quality and service. It’s essential to do your research.

A reliable Ice Machine Factory should understand your specific needs. Some may offer advanced technology, while others focus on cost-effectiveness. You might struggle with finding the right balance. Pay attention to customer reviews and machine specifications. The details matter greatly.

It’s important to reflect on your goals. What volume of ice does your business require? How often will you need maintenance? These are vital questions. Making a choice without thorough evaluation could lead to regrets later. A poor decision may impact your business operations more than you think.

When evaluating ice machines for your business, it's crucial to understand the different types available. Each type serves unique needs. Traditional cube ice machines are popular for bars and restaurants, delivering consistent ice cubes. Flaked ice machines are ideal for seafood and produce markets, as they maintain freshness. Nugget ice machines provide soft, chewable ice, perfect for fast food eateries and hospitals.

Tip: Assess your business type to determine the right ice machine. Consider the volume you will need daily.

Don't overlook user maintenance. Some machines require more upkeep than others. This may lead to unexpected costs or downtime. Also, think about energy efficiency. Some models consume more power, affecting your bill. Failure to recognize this can impact your budget.

Tip: Calculate the total cost of ownership, not just the upfront price. Ensure the machine fits your workspace too. An oversized machine can limit operations.

When seeking an ice machine factory, understanding key factors is crucial. Production capacity stands out as a primary consideration. According to industry reports, a well-established factory should meet a minimum output of 500 pounds per day for larger businesses. Choosing a factory that meets your demand can significantly affect your operations.

Quality assurance is another vital aspect. More than 20% of businesses report issues with inconsistent ice quality. Verify a factory’s certifications and past performance data to ensure they meet your standards. Also, pay attention to service and support options. Timely maintenance is essential to prevent costly downtimes.

Cost is also a factor, but it’s important not to compromise quality for savings. The best factories may charge more upfront. However, they often yield longer-lasting products and reduce overall costs. Take a moment to weigh the short-term expenses against long-term value.

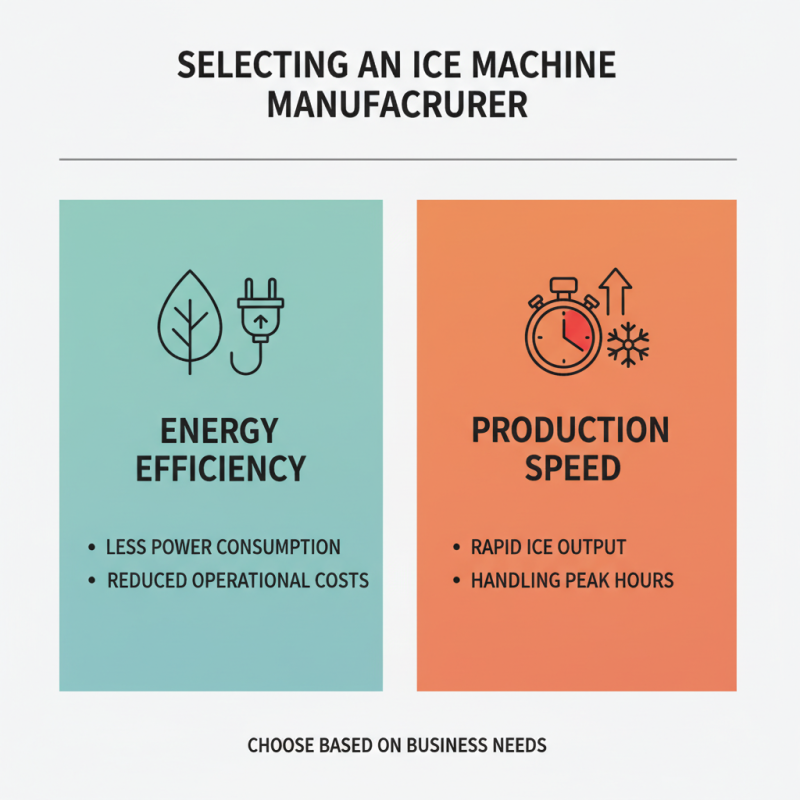

When selecting an ice machine manufacturer, it’s crucial to consider their unique offerings. Some companies focus on energy efficiency, providing machines that use less power while producing high-quality ice. This innovation can significantly reduce operational costs over time. Others emphasize their machines' speed, offering models that churn out ice quickly during peak hours. It’s essential to choose one that matches your specific business needs.

Another aspect to evaluate is the design and size of the machines. Some manufacturers offer compact machines suitable for smaller spaces. This option can be ideal for cafés or bars with limited counter space. However, larger establishments might require industrial-sized equipment to meet higher demands. It’s easy to overlook specific features like water filtration systems or maintenance access. These details can affect long-term performance and upkeep.

It's crucial to compare customer support services as well. Some manufacturers provide robust training and troubleshooting resources. This support can be invaluable for new users learning to operate complex machines. Others may lack comprehensive guidance, leaving operators to troubleshoot on their own. Finding a balance between features and support can lead to a more efficient and satisfying experience in ice production.

When assessing the quality and reliability of ice machines, consider key factors like durability, efficiency, and output capacity. Industry reports indicate that 30% of commercial ice machines fail within the first four years. This statistic highlights the importance of thorough evaluation before purchase. Look for machines that follow strict industry standards to ensure longevity and performance.

Inspect the construction of the machine. Sturdy materials like stainless steel often signify better durability. Energy efficiency is crucial too, as machines with higher Energy Star ratings can reduce operational costs by up to 40%. Many businesses overlook this, leading to higher expenses over time.

Don't forget maintenance needs. Regular upkeep can extend a machine's lifecycle significantly. A report shows that poorly maintained machines consume 20% more energy. Evaluate warranty options as well. A comprehensive warranty reflects the manufacturer's confidence in their product's reliability. Remember, the right choice is not just about immediate needs but long-term sustainability.

| Model | Ice Production (lbs/day) | Storage Capacity (lbs) | Power Consumption (kWh) | Warranty (Years) |

|---|---|---|---|---|

| Model A | 500 | 250 | 3.5 | 3 |

| Model B | 600 | 300 | 4.0 | 5 |

| Model C | 450 | 200 | 3.0 | 4 |

| Model D | 700 | 400 | 5.0 | 2 |

When selecting an ice machine factory,

maintenance and support services should be a priority. A reliable factory offers

robust support to ensure your machine runs smoothly. Regular maintenance

is essential for optimal performance. It helps to prevent unexpected breakdowns and

prolongs the life of the equipment. Each service visit should include cleaning,

checking mechanics, and replacing worn parts.

Some factories provide online tutorials and troubleshooting guides. These resources

empower business owners to resolve minor issues quickly. However, not all factories offer

the same level of support. Some might lack proper training for technicians.

This can lead to frustration and additional downtime.

Reflecting on your needs can help in choosing the right factory.

Communication is crucial when it comes to support services. Factories should have responsive

customer service. They should be reachable via multiple channels. Delays in communication can

hinder smooth operations. It's vital to weigh these aspects carefully. A factory's support can

make a significant difference in your business's overall efficiency.